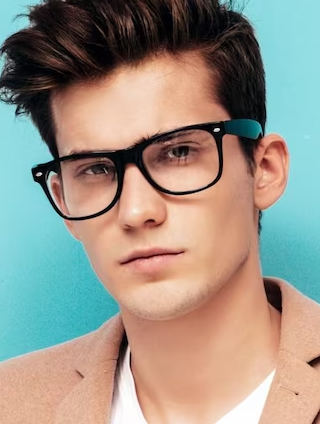

LENS MATERIAL

The main functional component of eyeglasses are the lenses. Lens can be highly customized with various treatments to meet your work requirements and improve your vision. These is a brief overview of the key benefits of each material

Plastic Lens (or CR39)

Plastic lens are a very popular and affordable option. The reason they are widely used is that they provide comfort and offer a wide range of vision correction. One drawback of plastic lens is that they easily get scratches so to avoid this problem scratch-resistant coats are applied on the lenses to make it more durable. These lenses are usually used for light prescriptions that range from +/-1.75. These lenses are included with every non-safety adult frame.

Polycarbonates

If you are looking for thinner and durable lenses up to 10 times as compared to a plastic lens, then polycarbonate lenses are the best choice. They also provide protection against ultraviolet radiation. If your prescription ranges from +/-2.00 to +/-4.00 or to be used by children under the age of 18 or the wearer has an active lifestyle or one who needs ANSI-rated safety protection, then polycarbonate lenses are the best choice.

High Index

High-index lens material is thin, light, comfortable and provides durability and protection from UV rays. These properties make high-index lenses great a great choice. They are thinner than plastic and lessen the ‘bug eye’ effect from standard lenses. Wearers with prescriptions greater than +/-2.00 are good candidates for Hi-index lens.

Trivex

This material was originally made for military uses. These lenses are comfortable, lightweight, durable, provide protection and a clear vision to the wearer. If you are looking for superior optical quality, then Trivex lenses are the best choice as they can be used with any prescription.