Last updated: Thursday, February 20, 2025

Personal protective equipment (PPE) is the indispensable right of every worker. It is worth mentioning March which marks the Workplace Eye Wellness month of the year. The need for ample eye protection training is imperative for the modern workplace. Experts unanimously agree that the adoption of protective gear for the eyes could reduce injuries by almost 90%. According to the National Institute for Occupational Safety and Health (NIOSH), 2000 workers are subjected to injuries on the job each year. Most of the injuries sustained by workers are related to eyes. Another study conducted by the Bureau of Labor Statistics (BLS) testifies that 60 percent of injuries to the eyes were a result of not wearing safety eyewear frames. Common injuries may include:

- Abrasion is a result of foreign objects entering and rupturing the eye’s cornea.

- Rubbing the eye as a result of irritation caused by the intrusion of fine particles such as dust.

- Splashes of liquid as a result of mishandling.

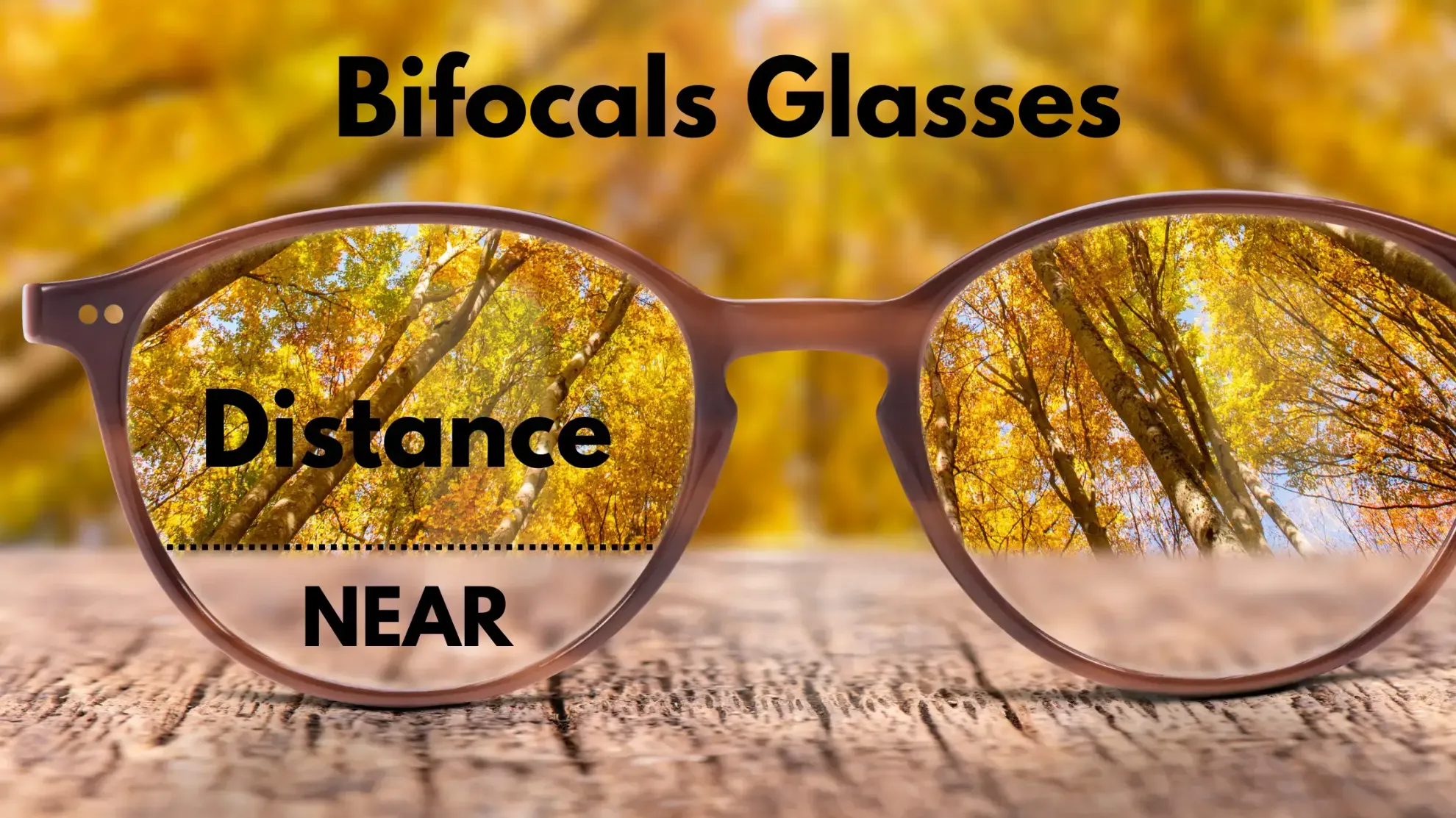

The aforementioned hazards can be avoided to a large extent through the implementation of a sound training program. This calls for a certain set of actions to be taken first. The Occupational Safety and Health Administration (OSHA) standards make it mandatory for employers to provide workers with a certain level of eye protection. This also includes prescription safety glasses for those having a refractive error in their vision. Before making your purchase, it is first important to ascertain a few things to educate & implement standards at work.

Assessing the Environment

It’s important to assess the working milieu before purchasing safety eyewear frames. According to BLS, some workers are more prone to sustain injuries working in certain industries, which are:

- Manufacturing; Construction & Trade Industries.

- Production; Installation & Maintenance; Repair & Extraction.

Conducting a thorough analysis of business operations is quite fruitful. This will help in discerning the kinds of hazards workers face. It will also aid in purchasing the right kind of protective gear. Monthly data on accidents could be extracted and used as a source of information. The frequency of accidents can be detected.

Choosing the Right Type of Safety Eyewear Frames

After an assessment of the environment, it’s important to select the right kind of equipment. The American National Standards Institute (ANSI) compliance ascertains the level of protection for eyewear. The ANSI Z87 ensures the quality of robustness against high-impact accidents. Various markings denote the kind of protection that is offered. For instance, the “D3” mark is suitable against splatter of toxic fluids. For protection against Ultraviolet (UV) rays, glasses with a “U” marking should be chosen. They are suitable in the case of workers involved in environments of extreme heat.

Conducting Eye Safety Training

Employers should evangelize the need for wearing eye protection gear at work. According to a study, companies face a cost of $300 million each year as a result of work-related injuries of employees. This could be reduced by a huge margin through safety training programs. Regular eye checkups should be conducted for employees requiring RX safety glasses. Management needs to step up and support the needs of workers.