Last updated: Thursday, September 25, 2025

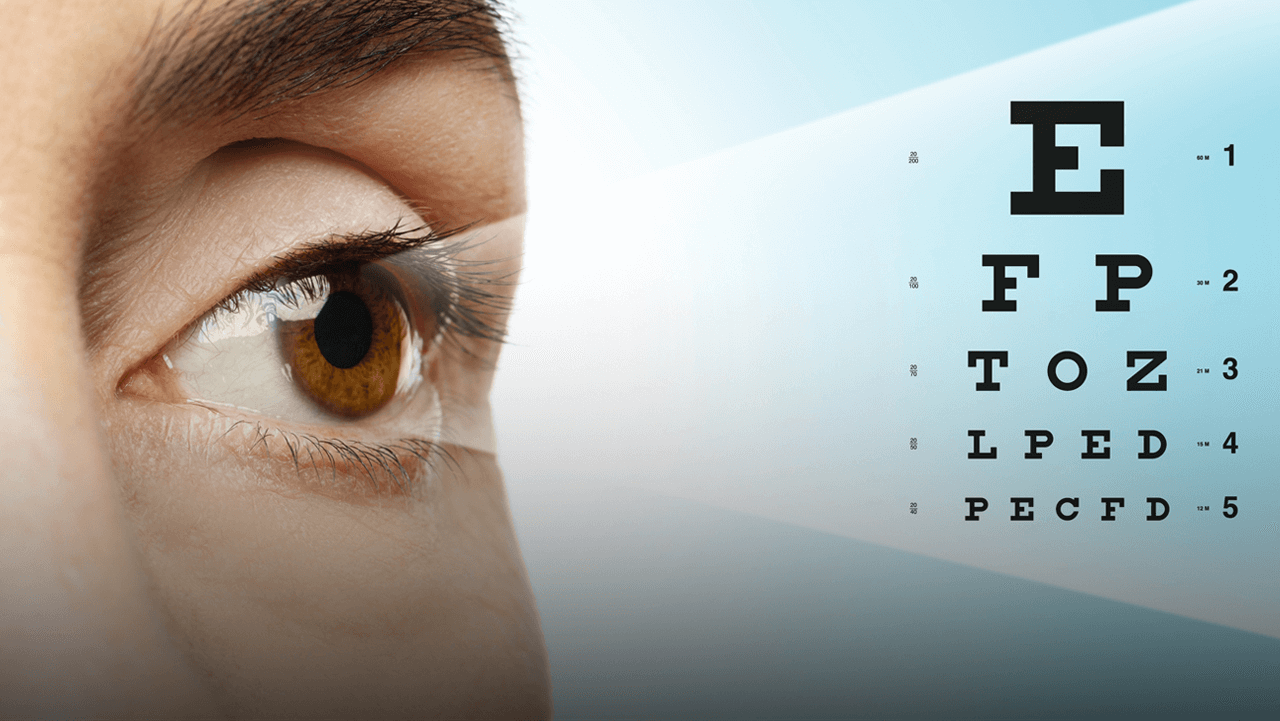

When deciding between different materials for protective eyewear, it’s important to consider the pros and cons associated with them. Along with a variety of choices offered in protective eyeglasses for work, the most popular ones among them are glass & polycarbonate lenses. Lens material sets the basis for different lens coatings. So which one’s the best for eye protection PPE? Here’s a rundown for you to better understand which one suits you right.

Glass Lenses

Probably the most commonly used material for prescription lenses, Glass lenses have been around for a long time due to their availability. However, due to the increased use of polycarbonate material, glass lenses have started to lose popularity.

Advantages

- Probably the best compound to protect against scratches. You could opt for these without having to worry about getting an additional anti-scratch coating to maintain its flawless appearance. Glass lasts longer when it comes to sustaining the damage caused by wear & tear through usage. Overall, it’s low maintenance.

- It offers greater clarity of vision than polycarbonate lenses. There’s a reason why it is used in machines that require inch-perfect optical precision, such as camera lenses or telescopes.

Disadvantages

- Glass is brittle, which is the core reason why it is prone to shattering or cracking very easily under the force exerted by a high-impact accident. This can be extremely dangerous when wearing your eyewear in a hazardous environment at work.

- Adding a higher prescription index can make your glass lenses a bit heavy & burdensome to wear for long hours. This can be frustrating for someone who has to wear safety goggles at work.

- Another disadvantage is that glass material does not offer sufficient protection against UV rays, thus making it a poor choice for most sunglasses without UV coating.

Polycarbonate Lenses

The staple material used in all ANSI Z87.1-rated branded eyewear, such as 3m safety glasses, is along with many others. Polycarbonate has become the core material for lenses to be used in any protective eyewear that guarantees safety assurance as prescribed by OSHA.

Advantages

- Polycarbonate is high-impact resistant, which means shatterproof protection in most cases. This material is ten times stronger than glass or plastic lenses.

- Effectively blocks out 100% UV rays of types A & B to prevent illnesses such as cataracts or macular degeneration. This is why branded protective eyewear, such as Wiley X Safety Glasses, comes with polycarbonate lenses.

- Extremely lightweight & flexible, which makes them easier to remove & then put back again.

Disadvantages

- Most polycarbonate lenses have to be used with an anti-scratch coating to prevent premature damage to the lens surface.

- They offer a lower level of optical clarity than glass. This is often complained about by most people wearing protective eyeglasses that come with polycarbonate lenses.

Overall, it is safe to assume that polycarbonate safety glasses are a better choice for safety eyewear. For some, glass material may take all the points when it comes to wearing normal prescription eyeglasses.