Are you aware of everyday eye injuries by working experience? This is around Figure 2000, and all of these workers get eye injuries while performing hazardous tasks. Besides, according to another statistic, around 10 to 20% of eye injuries are temporary or vision loss forever.

How scary a statistic? Because all of us have only two eyes for our entire life. Therefore, you need to protect yourself at any cost and do the best you can. However, it is not easy to take out big cash from your wallet for the sake of the best safety glasses. But the most considerable thing is that cost can increase if you get an accident that leads to a thoroughly preventable eye injury.

Thus OSHA stands for Occupational Safety and Health Administration, and many more professional eye care also agree with the truth that most injuries are preventable. You have a convenient option to shield your eyes with appropriate safety gear while working in a hazardous environment. Keep remembering the right gears depend on your work nature and the risk level of the danger.

For example, you are performing homemade projects that need specific safety rather than the threat of chemical splash. Therefore, be conscious of your requirements and then go shopping for safety eyewear with accurate features.

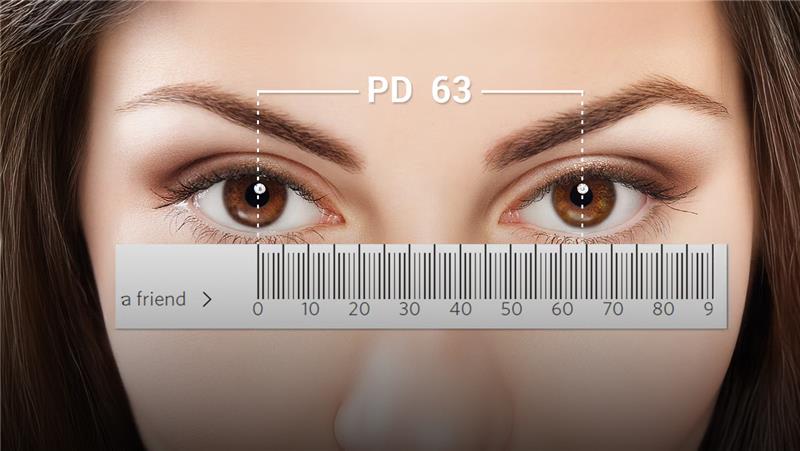

Whether you are participating in home improvement projects or playing some action sports, eye injuries have no time. Therefore, get the best suggestion from your eye doctor for the most suitable eyeglasses as per your work requirements. Appropriate measurement can lead to adequate protection of your eyes from damage. Never ignore using the best safety glasses because your eyes are more precious than your style and look.

Many Industries are at risk of eye injuries, Here are the top 8, who is at the greatest risk of eye injuries

- healthcare industry

- Carpentry industry

- Electrical work industry

- Welding industry

- Plumbing industry

Let's find out the most typical eye hazards in a different work setting. After this, you will find the best ways to shield your eyes.

Chemicals:

Eye injuries also happen due to mists, fumes, vapors, and chemical splashes. No doubt, direct interaction with dangerous chemicals could be severe, and even sometimes, these injuries are irreversible. Many people refer to chemical words with lab settings that contain harmful products.

But even if you use some basic stuff can be dangerous for the eyes, and you remain in contact all over the day. Cleaning products, paint products, gasoline, grease oil, and many more items can lead to serious injury. Thus, people who are engaging in chemical splash industries should have an easy approach to the eyewash station.

And this facility merely does not belong to the service experts and oil field service providers. Make sure every worker has bottles of eye saline in their first aid kit. They can easily flush out chemicals from the eyes if a similar case is in distant areas. Besides, these small bottles are easy to access treatment if something like this occurs.

Dust:

Unarguably, dust is a common eye hazard that many workers face, particularly, when they are in an outdoor environment. So, the workers who have jobs in woodworking, oil and gas factories, mining, and construction, deal with these hazards regularly. Although dust according to many people, is harmless, it can lead to severe diseases. For example, you can get short-term trauma which is extremely painful and tiresome as well.

Protective glasses are most of the time used by workers for eye protection from dust. Keep remembering there are fine particles in the dust that are highly irritating to the eyes if you get them. Due to their small size, they can escape from gaps between the human face and specs.

Therefore, goggles are a better option than simple work glasses. If you are not willing to wear bulky shape goggles, buy full-rim or wraparound eyeglasses. Besides, grab a safety pair with a rubber seal or have full foam around your eyeglasses frame. They will perform better in shielding eyes than basic safety specs.

Flying Objects:

Flying objects are also considered common eye hazards like dust. Any loose particles like airborne pieces or particles can pose an eye hazard. Common flying particles are metal elements, wood particles, and cement chips. Flying objects can come from nearby work settings as well. Different tasks that can include particles are grinding, hammering, chopping, sanding, machining, and many more things in these fields.

Besides, some large objects or tools can accidentally hit your face or eyes. Materials can fly into the eyes of another person. Thus people need to use safety eyewear. Make sure your surroundings are safe and have appropriate safety gear. You never know when danger can come and strike your face. Even it can injure you. Therefore, protection is better than treatment.

Penetration:

Another most dangerous thing is the penetration of any objects or tools because it occurs unexpectedly. If something like an object penetrates the eyes, it can lead to severe damage like permanent blindness. Nails and staples are common elements that can easily penetrate the eyes.

Therefore, simple work glasses are enough to shield your eyes. Well, always use common sense and try your best to stay away from these unexpected objects. Avoid spreading the mess around you with staples and guns because you are preparing danger for yourself. Keep assuring everything is clean before working with them. If any element penetrates the eyes, immediately look at medical care and don’t even try to remove it by yourself.

Optical Radiation:

Laser operation and welding works produce high-level heat, UV rays, and infrared rays. Unprotected eyes get cataracts, blindness, and retinal burns. Keep member optical radiation is serious. Cover yourself with the proper hoods and safety glasses while performing such serious tasks.

You need to check out the appropriate OSHA regulations and ensure that you use the best protection level. The lens tint for the safety glasses relies on the concentration of rays produced through these sources. Besides, you may be required to ask the safety expert if any support is required.

Eye injuries occur in the blink of an eye. And of course, you have no extra time for reaction before happening eye injuries. Therefore, you need to ensure you are ready to use the most suitable eye safety.

How Do Defend Eyes from Sudden Injuries?

Well, there are a few things that shield eyes from unexpected injuries.

- Figure out the exact hazards at your job site

- Remove all dangers before initiating your work through work screens, machine guards, or other controls.

- Use appropriate safety for eyes.

- Try to keep safety glasses in the fittest condition and immediately replace them in case of damage.

- The selection of appropriate safety specs should be as to the danger requirement regarding every activity.

There is Essential Eye Safety Including.

- Prescription and non-prescription safety eyewear is the first safety. However, safety eyewear is also the same as regular dress eyewear. But they are particularly created for eye safety. The safety frames and lenses have a higher impact than standard eyewear. Besides, protective glasses should meet the ANSI safety standard and must look at the Z87 mark on either frame, lens, or both.

- Protective eyewear delivers ultimate safety in particular working settings where there are a lot of flying particles, ships, and dust exposure. Wraparound frames or removable side shields provide extra protection from the sides of the eyes.

- Protective lenses are designed with either Trivex, plastic, or polycarbonate material. All these materials are impact and can stand easily against any danger to shielding eyes. But you need to ensure that all materials meet ANSI standards so that they can deliver you maximum safety when a threat is around.

- Goggles deliver the highest level of safety from dust, chemical splashes, and other impacts. Safety goggles are also shattered resistance like safety specs. Besides, they offer secure protection around the eyes area and shield them from dangers coming from any angle. Furthermore, safety goggles can be used over contact lenses or prescription eyewear.

- Helmets and face shields are also decent protection while working with toxic things like heat or chemicals. For example, helmets are excellent safety against welding or working against hot chemicals. Helmets and face protectors are not only adequate protection because they are always embedded with safety goggles or safety glasses. So that your eyes remain protected after removing side shields. Hence goggles and helmets have specific filters to shield the eyes from harmful radiation. These radiations are emitted when you are engaging with laser or welding work.

One important thing about safety glasses is the perfect fit around the eyes for ultimate safety. Therefore, you need to maintain safe eyewear to prevent dirt objects or scratches. When these things come in contact with the lenses create scratches that can lead to glare and hampered vision. So, whatever your earning profession, always use appropriate safety because it will secure you from all hazards.

Are Contact Lenses Secure for Industrial Working?

Keep remembering contact lenses are not adequate safety for the eyes against dangers present in the working area. But still, there is no genuine cause not to use contact lenses or lead to an eye injury.

Contact lenses enhance worker protection and productivity due to sharp vision in working workplace. People who use prescription contact lenses have more sharp eyesight than eyewear. They don’t create visual distortion in case of higher prescription. Besides, safety goggles or safety glasses can easily fit over lenses and keep eyes comfortable while in a working environment.

Summary:

So, whether you are working in a high-risk environment or not, it is a decent step if you go towards a comprehensive eye exam. You will be ensuring the top shape of your eyes. Always use the most satisfactory safety for your dangerous work zone.